What is PAT Testing?

Portable appliance testing (PAT) refers to the inspection and testing of electrical appliances and equipment to assure they mee safety standards. It is important that all the appliances and equipment pose no threat to the safety of the people working or living in a property.

PAT testing is carried out in offices, businesses, shops, rental properties, care homes, warehouses, fairgrounds etc. PAT testing is essential in any building where there are employees, rental properties or public sector buildings.

What is the legal requirement for PAT testing?

The law simply requires employers or landlords to keep their electrical equipment in good working order in order to avoid hazard. It does not specify how or how frequently this should be done.

Employers and landlords should take a risk-based approach, taking into account the type of equipment and its intended use. Testing (together with visual checks) can be a vital element of a successful maintenance plan, providing employers and landlords confidence that they are doing what is necessary to assist them in meeting their legal requirements.

HSE gives recommendations on equipment maintenance, including the use of PAT tests. It is important to note that whilst not a legal requirement, in the event of an accident resulting from unsafe equipment an employer or landlord must display their desire to carry out due diligence in ensuring safety of such equipment.

An example of lack of diligence in this scenario would be to purchase used equipment that may show signs of wear and not properly examined or tested prior commissioning for use by an employee or tenant.

Do I need to keep records of PAT testing in my rental property?

There is no regulatory requirement to label inspected or tested equipment, nor is there any requirement to record the findings. A record and/or labelling, on the other hand, can be a beneficial management tool for monitoring and analysing the effectiveness of the maintenance scheme – as well as demonstrating that one exists. However as company we deem it best practice to label all tested equipment and ensure they are labeled accurately with date of inspection and subsequent renewal due dates. In addition we issue a digital certificate that contains further information about the tests which is emailed to the customer on completion.

Why is a PAT test necessary for landlords?

So why should you I as a landlords care if it’s not required by law to carry out a PAT test, you may ask yourself. You can better fulfil your responsibility to your tenant by doing a professional PAT test on any appliances you give in your rental property.

In England during 2018-2019 electrics were responsible for 14186 fires in the home. This 53.4% of all accidental house fires. Malfunctioning electrical appliances accounted for 3667 or 25.9% of those fires according to Electrical Safety First. This is a significant number of fires that can be avoided by carrying out regular appliance testing.

Your tenant will be significantly less at danger if you make sure all electrical items are safe to use. Additionally, you can demonstrate that you did everything reasonably possible to safeguard your tenant’s safety if they are hurt by a tested and approved appliance you gave.

How often do I need to carry out PAT testing in my rental property

Because each environment and appliance requires different measures, the Health and Safety Executive (HSE) makes no specific recommendation for how frequently PAT tests should be performed.

Before a new tenant moves in, landlords should have all of their appliances PAT tested. Following that we recommend appliances are tested every 12 months or at change of tenancies to ensure continued safety.

Do I need to PAT test my tenants electrical appliances?

As a landlord you are only responsible in ensuring the appliances you have provided are safe to use. You are not obliged to test equipment or appliances brough to the property by the tenant but should advise the tenant to do so as future accidents and fires can be caused by faulty and unsafe equipment.

An inspector carrying out a PAT test should show due diligence and highlight safety issues that are clearly visible on the tenants’ equipment even though they were not instructed to do so.

What is the difference between an EICR and a PAT test ?

An EICR or Electrical Installation Condition Report is an inspection of all electrical installations and fixed wiring within a property. Depending on the condition of the installation the electrical engineer visiting the property may issue a certificate ranging from 6 months – 5 years. This may or may not have some recommendations or urgent observations listed on the certificate depending on the severity of the issues.

As of 1st of July 2020 EICRs are a legal requirement for all tenancies however PAT testing is currently not mandatory. It is also important to note that electrical engineers qualified to carry out an EICR may not be trained or equipped to carry out PAT testing and vice versa.

Is it likely that PAT testing become a legal requirement for private sector landlords?

With the government increasing the emphasis of safety on landlord legislations, it’s entirely possible that PAT testing will become mandatory for all rental properties in the foreseeable future. Portable Appliance Testing, along with Electrical Installation Condition Reports, has been a legal requirement for landlords in Scotland since 2015. England and Wales already implemented mandatory Electrical Installation Condition Reports earlier this year, so it may only be a matter of time before PAT testing is added to the list.

Electrical Equipment Testing (EET) compared to PAT testing in place of work

The name given to electrical testing of appliances has changed. EET will replace the previously known PAT testing to (Electrical Equipment Testing).The term ‘Electrical Equipment Testing’ has a broader meaning and wider inclusion in terms of what items are included in the test. This eliminates any misunderstandings about the previous term and what equipment is covered by it.

Is it an appliance or an equipment?

While the industry is familiar with portable appliance testing, most workplaces are interested in those things that have a plug and are to an extent portable. However, in standards, an appliance is defined as “apparatus intended for household or similar use,” which obviously excludes many types of electrical equipment found in the workplace. It’s also worth noting that, with a few exceptions, the Electricity at Work Regulations do not apply at home in a domestic setting. It is clear that the term ‘appliance’ is not representative of what the regulators are seeking, which is ‘electrical equipment’ that is ‘in-service,’ i.e. used at work.

When it comes to ‘electrical equipment,’ the Code defines it as “any item for the generation, conversion, transmission, distribution, or utilisation of electrical energy, such as machines, transformers, equipment, measuring instruments, protective devices, wiring systems, accessories, appliances, and luminaires.” Washing machines and vacuum cleaners are examples of electrical equipment.

This is a fairly broad definition that encompasses the majority (if not all) of the electrical equipment found in a workplace. As a result, the upcoming 5th Edition of the Code emphasises the original intent of managing electrical equipment in the workplace that is not covered by other maintenance regimes, such as the electrical installation itself. The equipment, such as an air conditioning unit or a security access control system, may not be equipped with a flex and plug and may be hardwired into the installation. These types of equipment frequently slip through the cracks of in-service inspection and testing, with the person performing the Electrical Installation Condition Report (EICR) stopping at the fused connection unit or isolator supplying the equipment and the ‘PAT’ tester seeing it as part of the installation itself, rather than a portable appliance.

As a result, the words ‘portable’ and ‘appliance’ appear only in the preface’s explanatory notes in the 5th Edition of regulations. Another related change is the elimination of the terms ‘stationary,’ ‘portable,’ ‘fixed,’ and ‘moveable,’ as the primary focus is on the verification of equipment for safety in continued use. The ability of the equipment to move or be relocated (or not, as the case may be) has no bearing on the nature of the testing and inspection required, though it may have an effect on the frequency of the maintenance activity.

Does New equipment or appliances need to be PAT tested?

It should not be necessary to do a formal portable appliance inspection or test on new equipment because it should be supplied in a safe condition. However, a straightforward visual inspection is recommended to confirm that the item has not been damaged in any way.

Can I carry out my own PAT testing?

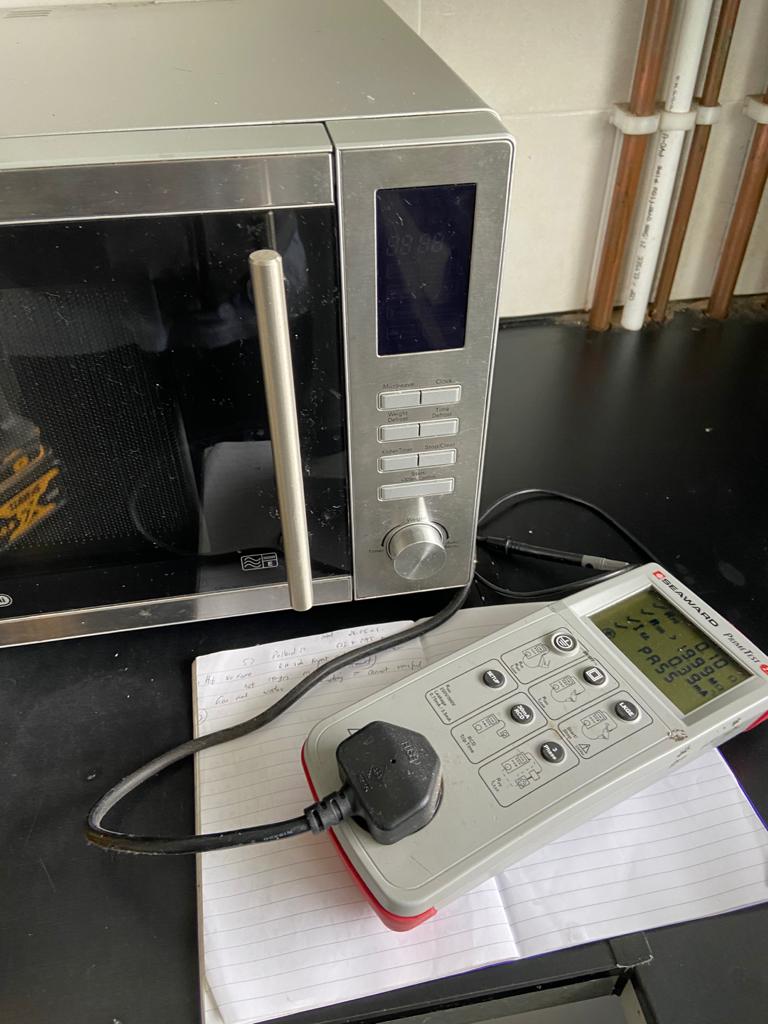

The law requires the person carrying out the Portable Appliance Testing to be deemed competent. This requires completion of the necessary training in order to

- Have knowledge of and use the right equipment to test

- Be able to the use the equipment correctly

- Be able to understand and communicate the results correctly

- Ensure the Portable Appliance Tester is correctly calibrated.

Although you may not be a qualified PAT tester but if you have a basic understanding of electrical equipment and their safety requirements, it is good practice to carry a visual inspection of any equipment or appliance prior to use.

What happens if an appliance fails a PAT test?

Basic issues that may fail an appliance may be easily rectified during the visit. Some of the most common causes that can be easily resolved are

- an incorrectly fitted plug,

- damage to the cable or

- incorrectly fitted fuse.

An inspector may wish to resolve these faults rather than failing the test. More complicated issues will perhaps require an appliance specialist or parts.

Failed and unsafe appliances MUST be decommissioned, which usually involves removing the plug and affixing a fail label.

What are the most common reasons for a PAT test failing?

Wrongly rated fuses

Despite their being a generally accepted standard for newly manufactured electrical appliances, PAT testing routinely reveals improper fuse ratings used.

A 3A fuse should be used for any modern item that draws less than 700W of power, and a 13A fuse for anything that draws more than 700W.

Despite its usefulness and the fact that it was created to streamline operations, this is not always followed and has room for improvement.

Each 1000W draws about 4A of current, thus a fuse rating somewhat higher than that is needed to safeguard the wire, and a 13A wall socket can handle up to 3000W of electricity.

A fuse is designed to be blown by an electrical surge when an appliance develops a problem, breaking the circuit and preventing any further damage from the excessive current. A cable fire can be caused by a buildup of heat over time if the fuse rating is too high and it does not blow.

Damaged or badly fitted plugs

A recurring issue seen by inspectors is broken or damaged plugs. Users tend to continue using broken plugs even though they are relatively easy to replace.

Broken plugs can lead to electrical shocks where live components become accessible. Similarly badly fitted plugs can be open to exposure and loosely fitted wires could for example lead to the earth wire coming away and not providing the intend function of providing protection by means of earthing the appliance.

Insulation resistance failure

The insulation resistance test ensures that the insulation that surrounds an appliances’ live parts has a sufficiently high resistance level. Failure of this test means there is risk of exposure to live parts and would result in failure.

Non-Insulated Live parts generally around plugs.

Modern plugs are insulated around the live and neutral pin to avoid incidental shocks, whilst not very common they can be seen from time to time and this issue can be easily resolved by replacing the plug.

Similarly damaged or missing parts around the appliance such as a missing cover can also expose live parts and will result in failure unless repaired or replaced.

Power or supply cable damage

Excessive cable wear is also a safety concern, thus any cable that shows signs of being overused should be replaced immediately.

In the UK all power/supply cables are surrounded by two layers of sheathing. Inner sheathing that most commonly has yellow (earthing), brown (live) blue (neutral). This then further surrounded by an outer sheathing most commonly black or white. Any signs of wear or damage to the outer or both sheathings is a serious concern and should be remedied immediately or the appliance will receive a failed test result.

What User Checks and visual inspections will be carried out during a Portable Appliance Test

The majority of flaws or damage can be seen by simply looking. Users should be urged to examine electrical equipment critically in their own homes or places of employment.

After safe disconnection, the following warning signs can be seen on the cable and plug of the equipment being examined:

- No serious physical damage to the appliance itself that could affect the integrity or electrical safety

- damage to the cable covering, such as cuts or abrasions

- damage to the plug, such as a cracked casing or bent pins

- non-proprietary cable joints, such as taped joints

- where the cable enters the plug or other equipment, the outer covering is not gripped. Check to see if the internal wires’ coloured insulation is visible

- appliances that have been used in unsuitable circumstances, like a dusty or wet environments

- damage to the equipment’s exterior cover or visibly apparent loose screws or parts

- Signs of overheating such as burn marks

What are the Classes of PAT Appliances and What They Mean

Class 1

These electrical devices rely on earth for safety as they are only insulated minimally. Such gadgets predominate in the market.

Class 2

These electrical equipment have additional insulation and need not rely on the earth for safety. A double insulated marking (a square within a square) will often be displayed on the manufacturer’s plate of such equipment.

Class 3

When it comes to electrical systems, Class 3 (low voltage) is the most secure option. Although the power supply and cables may need to be PAT tested, they are exempt. The typical icon for these devices is a diamond with three vertical stripes inside.

What type of PAT test should be done for each class of appliance

A device’s class determines if and how it should be PAT-tested.

- Class 1 appliances require a full PAT test, whereas

- Class 2 devices need an insulation test.

- Class 3 appliances don’t need PAT certification, but their charging leads and cords may.

PAT Testing of Extension Leads and Power cords

Extension leads and supply power cables (especially for IT) should be tested separately. Extension leads are possibly one of the most common causes of electrical fires, although this generally caused by overloading.

The safety of the extension itself should be carefully inspected and tested and never with another item connected to it. It is also good practice to test supply cables separately.

This may specially be the case for IT equipment as they can be sensitive and either need a softer test or a visual inspection only to negate the risk of damage to sensitive components.

Does the equipment in my business premises need PAT Testing?

Any business using electrical equipment should regularly inspect and test those products to ensure they are in proper working order.

HSE mandates that employers keep their premises free from any hazards to their employees, customers, and other visitors as per the Health and Safety at Work Act of 1974, Electricity at Work Regulations of 1989, Provision and Use of Work Equipment regulations of 1998 and the Management of Health and Safety at Work regulations of 1999

Hotel and motel owners, landlords, and other commercial property and lodging providers should also consider PAT testing to protect the safety of their visitors and tenants. This should be carried out at least once a year.

What are the different types of appliances or equipment that can be checked during a PAT?

Portable Appliances: A toaster, food mixer, vacuum cleaner, or fan heater are examples of portable appliances, which are defined as having a mass of less than 18kg and being designed to be moved while in use.

Moveable Equipment :Any piece of equipment that weighs less than 18 kg and isn’t fixed, like an electric fire, or that has wheels or other means of facilitating movement, like an air conditioner

Handheld Appliances This category of portable equipment includes items like a hair dryer, drill, and soldering iron that are designed to be used while being held in the hand.

Stationary Equipment This equipment, such as fridge- freezer or washing machine, has a mass greater than 18 kg and is not equipped with a carrying handle.

Fixed equipment, items such as a towel rail or bathroom heater, is referred to as “fixed equipment.”

IT equipment includes electrical business tools like computers and mains-powered telecommunications gear, as well as other tools for everyday business use.

My appliances failed a PAT test and I do not agree.

If you do not agree with a previous contractors PAT testing results you are within your rights to request the validity of tests and equipment used. Aged Pat testing equipment that have not been serviced or calibrated regularly can produce incorrect readings. Our engineers use the latest equipment and we regularly calibrate these and keep records to ensure the most accurate results